Reviewing the Benefits of Aftermarket Parts in the Maintenance of Equipment and Heavy Tools

In the realm of machinery and heavy equipment upkeep, the discussion bordering using aftermarket parts is one that stimulates inquisitiveness and motivates a more detailed evaluation. As experts entrusted with guaranteeing ideal efficiency and longevity of equipment, it ends up being vital to discover the benefits that aftermarket components supply. From cost-effectiveness to personalization alternatives customized to details needs, these elements present a compelling situation for factor to consider in the upkeep landscape. Allow's delve deeper into the realm of aftermarket components and discover the benefits that make them a viable option for industries reliant on efficient machinery operation.

Cost-Effectiveness of Aftermarket Components

Making use of aftermarket parts for machinery upkeep has been revealed to dramatically enhance cost-effectiveness without jeopardizing quality or efficiency. These parts, which are generated by third-party suppliers as choices to original equipment maker (OEM) parts, offer various advantages in regards to price and accessibility. Aftermarket parts are normally priced reduced than their OEM counterparts, making them a more affordable option for companies aiming to decrease upkeep expenses without compromising reliability.

One vital aspect adding to the cost-effectiveness of aftermarket parts is the affordable market they exist in. The availability of aftermarket parts is generally higher contrasted to OEM components, as they can be sourced from a variety of representatives and suppliers.

Wide Availability and Access

Aftermarket parts, understood for their cost-effectiveness in machinery maintenance, demonstrate significant advantages through their broad availability and access in the marketplace. Unlike OEM (Initial Devices Manufacturer) components that might be limited to details dealerships or suppliers, aftermarket components are widely generated by numerous third-party makers (Bobcat Aftermarket Parts). This widespread manufacturing results in a broad circulation network, making aftermarket components easily obtainable to consumers across various places

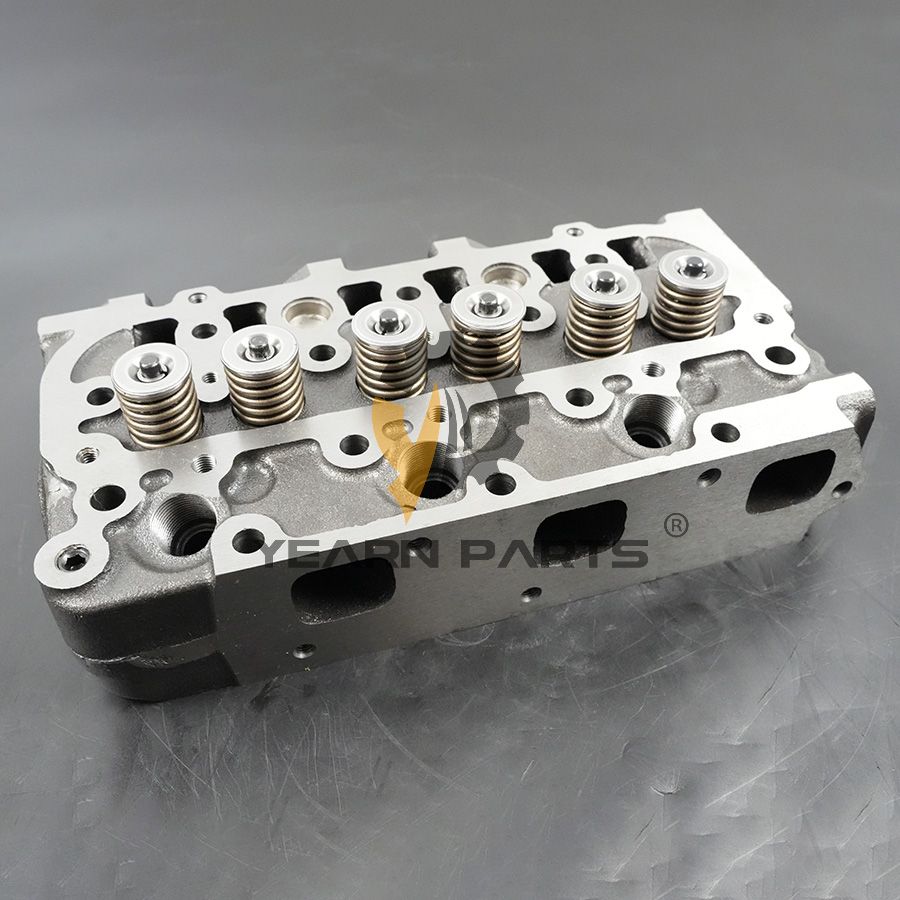

Equivalent Top Quality to OEM Components

With developments in manufacturing processes and quality control standards, aftermarket components currently supply a degree of quality that is similar to OEM components. In the past, there was an usual misconception that aftermarket components were of substandard top quality compared to original tools maker (OEM) parts. Due to technical progression and boosted competition in the aftermarket market, several aftermarket manufacturers have dramatically enhanced their production processes and materials to meet or also go beyond the high quality requirements established by OEMs.

Among the main reasons aftermarket components now match OEM parts in top quality is the extensive screening and certification processes that lots of aftermarket my latest blog post makers follow. These companies comprehend the relevance of producing top notch components that can perform reliably in various machinery and tools. Therefore, customers can now with confidence pick aftermarket parts understanding that they offer similar high quality to OEM parts at a more economical cost point.

Personalization Options for Details Needs

For machinery maintenance, aftermarket components supply a range of customization options customized to certain needs, enabling services to maximize their equipment efficiency successfully. Personalization is visit this page a crucial benefit of aftermarket parts as it enables companies to adjust parts to fulfill distinct needs that might not be attended to by typical OEM parts.

Additionally, aftermarket parts vendors can function carefully with services to comprehend their specific obstacles and style components that attend to these problems efficiently. Bobcat Aftermarket Parts. This individualized strategy to modification can lead to better equipment functionality, increased productivity, and lowered downtime as a result of tailored remedies that straighten with the business's functional goals. By leveraging aftermarket get rid of modification alternatives, businesses can enhance their equipment to carry out at its finest, eventually leading to enhanced overall operational efficiency and cost-effectiveness

Swift Distribution and Lowered Downtime

Given the customized solutions given by aftermarket parts for details equipment demands, businesses can gain from swift delivery and lowered downtime through efficient supply chain monitoring techniques. Time is of the significance in the commercial sector, where any machinery downtime can result in considerable financial losses. Aftermarket parts suppliers understand this seriousness and frequently excel in supplying quick distribution choices to reduce equipment idle time. By partnering with trustworthy aftermarket parts companies, services can access a vast array of products immediately, ensuring that repair and maintenance are lugged out swiftly to obtain equipment back up and running.

Lowered downtime is vital for keeping productivity degrees and conference task target dates. By having accessibility to a varied stock of aftermarket parts that can be delivered without delay, services can stay clear of prolonged periods of devices inactivity. This efficiency in supply chain administration not just saves time but additionally adds to cost savings by decreasing the impact of downtime on general procedures. Finally, the swift shipment of aftermarket components plays a crucial function in lessening downtime, enhancing operational performance, and eventually making certain the smooth functioning of equipment and heavy devices.

Conclusion

Unlike OEM (Initial Equipment Manufacturer) parts that might be restricted to details dealers or manufacturers, aftermarket components are commonly produced by different third-party producers (Bobcat Aftermarket read this article Parts). Furthermore, the competitive market for aftermarket components often results in lower rates and promotions, permitting customers to acquire top quality components at a lowered cost contrasted to OEM components

With advancements in making processes and high quality control criteria, aftermarket components now use a level of top quality that is comparable to OEM components. In the past, there was a common false impression that aftermarket components were of substandard top quality contrasted to original tools maker (OEM) parts.One of the primary factors aftermarket components currently rival OEM parts in quality is the rigorous screening and certification procedures that several aftermarket makers stick to.